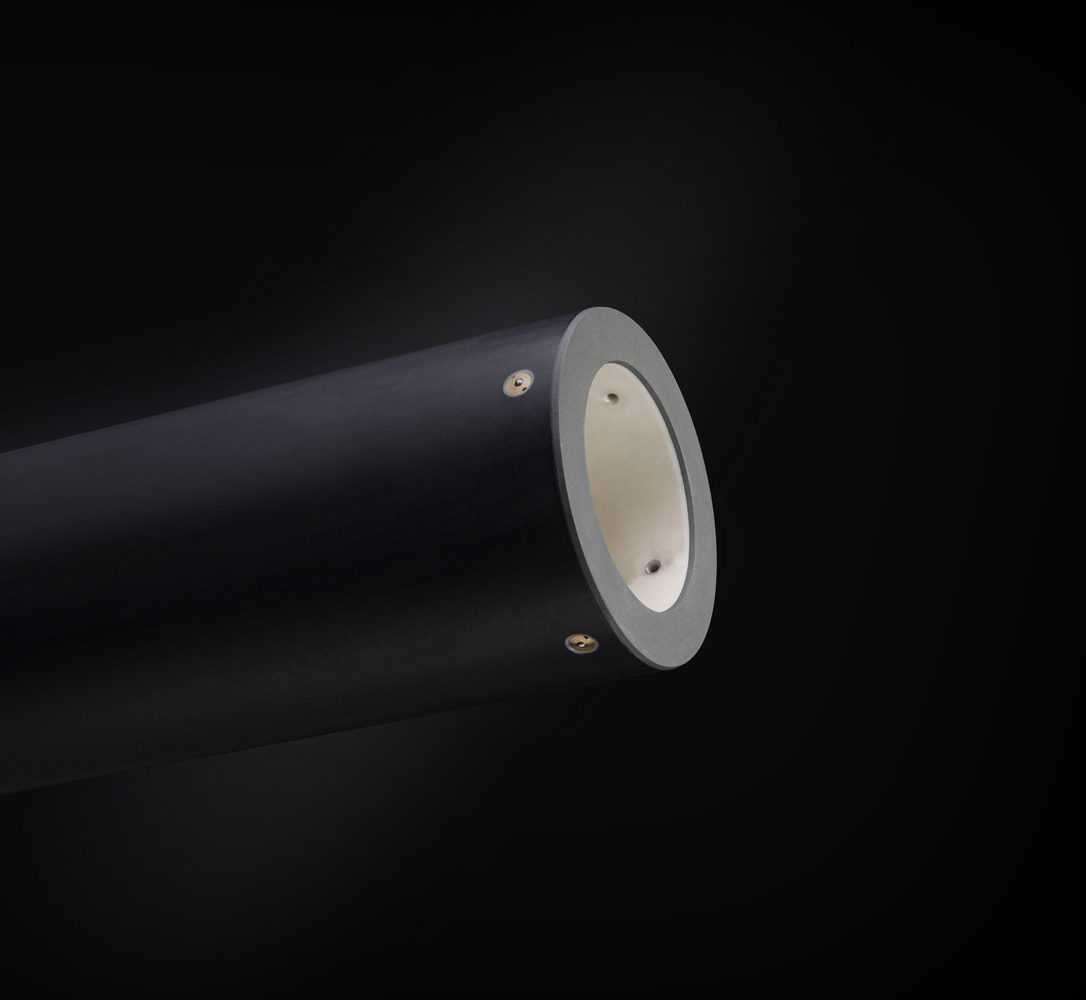

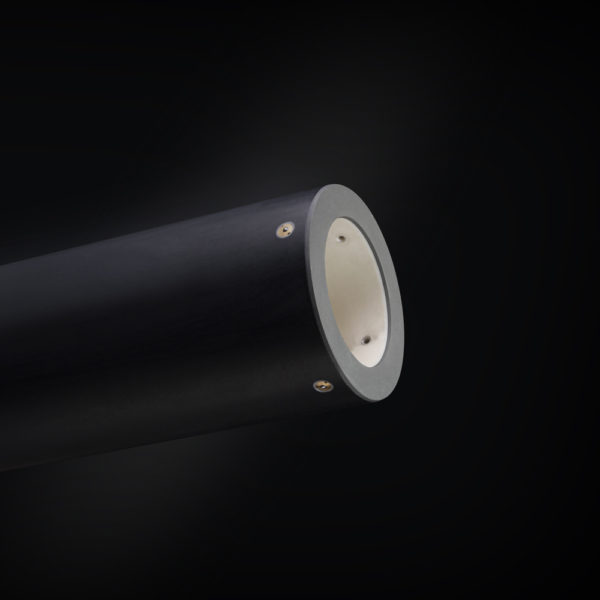

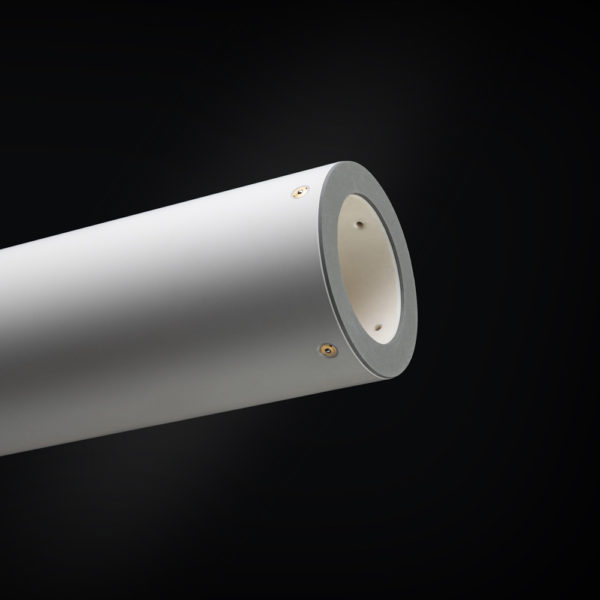

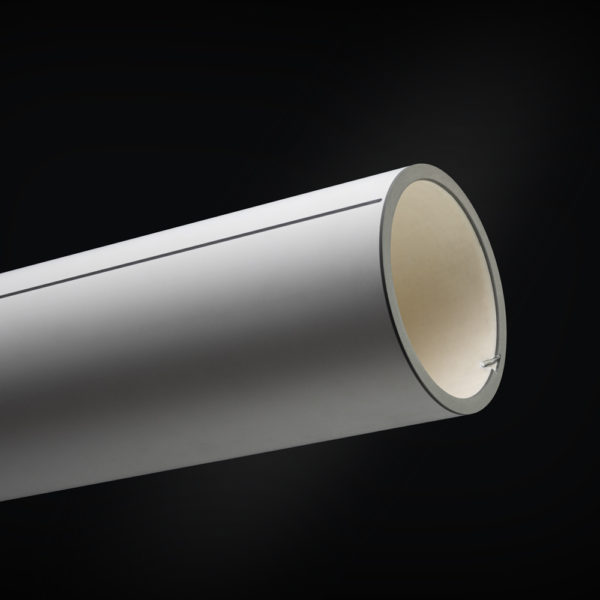

Carbon BS

Best in class Carbon Fiber Bridge

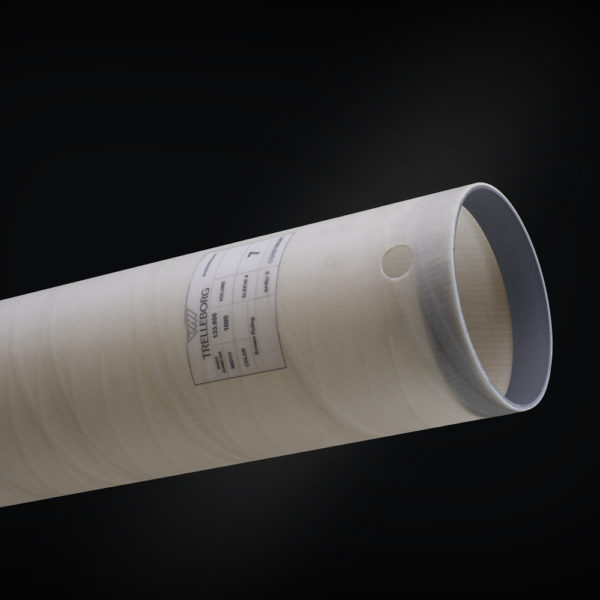

Bridge sleeves are commonly used on flexo presses to reduce sleeve weight, wall thickness and cost. Modern press productivity is sometimes offset by the nature of designs, causing vibration/bounce and visible streaks.

The Carbon BS Pneumatic Bridge technology offers exceptional dynamic response with exceptional reduction of bounce/visible streaks when it comes to printing demanding designs, as well as very low weight.

Features and benefits:

• Higher printing productivity thanks to structure damping properties and exceptional rigidity

• Reduced weight, especially on high wall thickness

• Smooth installation on press and quicker make ready

Technical datas

Application

Pneumatic plate mounting bridge

Alternative to hydraulic clamped bridge systems

Construction

High Modulous carbon fibre

Ventilation

Either via mandrel (flow through) or separate air supply

Tolerance on Outer Diameter

Nominal +/- 20μm

Tolerance on TIR

20μm

Surface

Extremely durable Epoxy & technical fabrics

Wall thickness range

From 16 to 100mm

Width range

From 500 to 2000mm

Stork Diameter range

From 210 to 1400mm

Weight reduction

Varies according to geometry

Thermal expansion

Nil in standard operating conditions

Conductive

Fulfill ATEX 95 requirements

Air supply

6 bars @ minimum 12l/sec

Cleaning

Any solvent compatible with UV, solvent and water based inks